- Cesar Silva Joins nFusion Capital as Senior Vice President, Business Development

- Patient Capital in Action: An Interview with Cambridge Savings Bank’s Yvonne Kizner and Cal Navatto

- The Growing Impact of Supply Chain Finance: Insights from SFNet's 2025 Market Sizing Study

- Secured Finance at Scale: Why the SFNet 2025 Market Sizing Study Matters More Than Ever

- Tiger Group Launches Investment Banking Division Led by Special Situations Veteran Jamie Lisac

PPE Funding Roundtable

By Eileen Wubbe

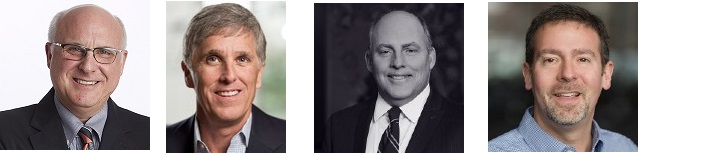

Four executives from SFNet member companies discuss their experience in adapting to the surge of funding requests for personal protection equipment (PPE). TSL Express sat down with Jeff Goldrich, president and CEO, North Mill Capital; Edward King, founder and managing partner King Trade Capital; Paul Schuldiner, executive vice president and purchase order finance division manager, Rosenthal & Rosenthal; and Scott Winicour, CEO, Gibraltar Business Capital to learn more.

Has here been more demand for funding requests from manufacturers looking to supply ventilators, respiratory masks, gowns and hand sanitizer?

Jeff Goldrich: We have existing clients and prospects who are getting large orders for all sorts of medical equipment and supplies. Much of it is sourced in China. We are facing several issues with that. One is that the Chinese manufacturing companies are requiring either large deposits or payment in full in advance before shipment. We have been working with purchase order finance partners to help with that. Another issue is getting goods out of Chinese customs, which is taking a long time, if at all. There are also complexities once inventory reaches the United States. We are continuing to aggressively advance on accounts receivable and inventory and taking steps to ensure that the products are what they are purported to be and destined for reputable customers. The companies we are working with are having some issues getting product properly inspected before it is shipped. We are adding new clients who are bringing in hand sanitizer, masks, privacy curtains for hospitals, among other essential COVID-related products. We are fortunate to have the liquidity and the team to get it done.

Edward King: We are working 12-16-hour days from our various locations to help finance the companies that know what they are doing when it comes to fulfilling PPE orders to hospitals, federal, state and local governments, along with corporate buyers. Being in the purchase order finance business, we are used to providing capital during the time of crisis as that is typically when companies have large spikes in sales to help with the situation. This crisis is unlike any other crisis we have seen in our almost 30 years. The volume of finance requests to sell PPE is probably 10 times any major event we have seen. Fortunately, we have lots of liquidity and experience in structuring and managing the unique risks of helping buy and deliver PPE inventory. We have standardized our information requests so we can collect as much information in advance to triage those companies that know what they are doing versus those trying to learn. We are laser focused on helping get the PPE to the frontline workers that need them.

Paul Schuldiner: Over the past few weeks, Rosenthal has seen a huge uptick in funding requests from importers, distributors and manufacturers trying to convert their operations to produce masks, gowns and other PPE to support healthcare workers on the front lines of the pandemic. We have also seen a great deal of activity among domestic distillers pivoting their businesses to produce alcohol-based hand sanitizers.

Many of these companies may be importing or making products they have never sold before, like a denim manufacturer now making masks. For that reason alone, it is critical that they engage with FDA-approved and certified factories. They need to understand the factory’s production capacity and payment terms before production even begins. Sending cash advances to factories overseas is never recommended, and those that demand cash in advance, escrow, proof of funds or deposits are typically not good partners for these types of transactions. If open payment terms with suppliers are not feasible, companies can mitigate their risk by obtaining letters of credit with a trusted lender. Now is not the time for a company to lose funds on something they could have controlled or negotiated ahead of time.

Scott Winicour: A few clients have asked us for additional capital to purchase equipment to increase production levels for PPE and related materials. In addition to that, we’re seeing some new business opportunities in which the prospect was in one particular line of business, but then adjusted either their manufacturing facility or their distribution efforts to be more focused on types of PPE, hand sanitizer, masks, gloves, things like that.

What are some of the major obstacles those companies are facing?

King: There are a myriad of risks buying and importing PPE from China currently. It is the wild west and importers of PPE need to make sure they are purchasing from properly authorized factories, inspect their goods and never let them out of their sight until the goods ship. Shipping has its own risks as in order to export companies need to make sure they have proper permits and when importing into the US there are other concerns. Newcomers to the PPE business should find trusted experienced partners on the ground in China.

Schuldiner: Unfortunately, crises like this pandemic can bring out the worst in scammers, fraudsters and inexperienced operators. We saw this play out in the wake of Hurricanes Andrew and Katrina and at other times when there has been a rapid and widespread mobilization of essential supplies. In these situations, extensive due diligence is always the best defense.

Rosenthal has been actively advising and supporting manufacturers and importers to ensure that they have the right processes and measures in place so that products can be produced, adequately inspected, and be shipped and delivered on time.

If manufacturers typically were not involved in producing medical supplies, how long did it take them to start up? Did they have to adjust their manufacturing lines to produce materials or pair up with other companies?

Goldrich: We are seeing a definite emphasis on PPE products from those companies that are already in the medical supply business. First, there is obvious huge demand and need so that is what gets the attention. We have not seen companies in unrelated types of manufacturing convert to PPE products.

King: Yes, almost everyone is pivoting to help in the most active part of our current economy, PPE supplies.

Winicour: The short answer is not very long. In one case, we’re talking to a client who took seven days from the time they adjusted their distribution and manufacturing processes to be more focused on PPE. In another case, the client just needed to get some more equipment in order to fulfill some orders for 3M when 3M ended up ordering a lot more product than initially anticipated. That one took a little bit longer as they had to get some additional equipment in.

Scott, are you seeing most manufacturers stop or slow down in other areas of production to have the opportunity to make PPE instead?

Winicour: We are seeing a mixture of situations. Some clients are focusing strictly on PPE because they have the ability to produce as much as they can. They obviously want to help the country and help the consumer. We have others whose core business is still doing okay, and they want to continue shipping product based on their core revenue sources. So, they are still producing both and have enough capacity for this.

How is PPE currently being manufactured with a disruption in the supply chain? Where are materials currently being sourced from and what are some of the hurdle’s manufacturers must overcome?

Goldrich: Ironically, because of where this originated, so much of the supply is from Asia with an emphasis on China. We have seen some domestic manufacturing and/or assembly. Again, what we are seeing is that the supply chain is centered in China and there is concern with quality and getting goods out of China in a timely fashion. Fronting cash to cover the manufacturers has obvious risk and we are seeing letters of credit being used for protection. We have not seen that in some time at least from our vantage point. Prior to this crisis, most of our import clients were buying from Asian suppliers on open terms but now, due to demand, upfront cash is required.

King: Most production is in China, but some is from Korea, India and now some from Viet Nam, but that changes based on the country’s own needs for PPE. There are many U.S.-based suppliers pivoting their business to help with production of PPE and hand sanitizers as well. The domestic suppliers are grappling with getting enough bottles, alcohol and other materials as the entire world is buying supplies at the same time.

Schuldiner: Masks, surgical gowns and other PPE are primarily being sourced from China right now. All the raw materials required for the final products are there so they can be cut, sewn, and assembled. Because cash is king, the problem arises when Chinese suppliers demand deposits and prepayments to make and ship the goods. With so much competition in this current climate, we are now even seeing freight companies require prepayment as well.

Another concern is that importers may be looking to buy PPE branded product from a well-recognized manufacturer making products in U.S. or European factories, but not from the brand themselves – a potential gray market effect. The federal government is now looking closely at re-importation of those products here, which could raise new issues.

In these situations, lenders must do their part to help control the “greed factor.”

Winicour: It varies client to client. There is slowness out there in the supply chain. Fortunately, when this started, a lot of our clients had stocked up for Chinese New Year as they were anticipating a slowdown. So in the beginning weeks of Covid-19 you didn’t see as much of an effect in terms of being able to ship product, but I think over the next couple of months, you might start to see a lot more pressure in terms of the supply chain as a lot of our client base uses up that excess inventory.

What we have seen, especially with the PPE products, is that some of our clients had to increase production and add some equipment. Some of their typical supply or their normal supply vendors are running into capacity issues as well. We have seen a couple of our clients reaching out to alternative vendors to get preapproved for the final customer to make sure they have that continual use of raw materials for their production.

How long after a company approaches you for financing does it take to get them to begin producing and shipping masks? How is quality control of the products being manufactured?

Goldrich: There does not seem to be a long lead time to begin producing. The issue is keeping up with demand. Our clients and prospects are less focused on masks and more on ventilators, hospital gowns, and other PPE. We are careful to make sure that deadlines and benchmark dates outlines in purchase orders are being met.

King: If we have complete information, we can propose within days. Once we get a signed proposal and our complete due diligence information, we can start funding within 5-10 business days if we can get responses promptly from our clients or outside parties such as factories, attorneys etc. We are usually ready to go faster than some other parties can respond.

Quality control may be the most important aspect of financing PPE. Factories must have proper approvals from the FDA etc. and then must be monitored closely during delivery of products. The inspection of goods is very important and requires qualified inspectors and processes to inspect and monitor goods.

Schuldiner: We have developed a criteria playbook at Rosenthal to help clients manage the myriad of issues they need to navigate to begin producing and shipping PPE. The most significant issue is getting over the pre-payment hurdle. If a factory will accept a letter of credit in lieu of pre-payment and if everything else lines up, our funding can be in place in 7-10 days, sometimes even sooner.

Having the right quality control and inspection procedures in place is also key. Relying only on the factory to handle inspections simply will not fly in this environment. As a purchase order funder, we require a third-party inspection company with experience in PPE and medical-related products to review the product before it ships to ensure that it meets FDA criteria. The factories themselves should also be FDA-certified. All logistics providers in the transactions should also have experience in supporting the movement of and customs clearance for FDA-related items.

For companies manufacturing domestically, it is all about the availability of the raw materials needed to make the PPE. In those cases, we provide funding for the direct labor as well as for the materials required for production.

What are some of the challenges associated with producing PPE and other products for federal, state and local governments and agencies?

King: Each government entity seems to have different requirements and standards. When selling to governments you need to make sure to understand the specific requirements of the sale and delivery. We advise that our clients get specific approval of the factories that are manufacturing, and the specific product being sold to a government in advance of importing and delivering any PPE. A company needs to understand if there are to be inspections before or after delivery by the government and what the acceptance terms are. In the current environment even if the government says they will pay COD it often takes many days to get pay due to the volume of invoicing and payment activity so companies need to be aware and stay on top of what they can do to get paid timely.

Schuldiner: With any transaction, it is important to study the fine points of the underlying contracts and orders for supplies, especially ones from state, local and other government agencies. The devil is in the details and the details mean everything in these transactions. For example, is your potential client selling directly to the federal, state or local government agency or are they getting orders from a “vendor” to those governmental or hospital groups? The credit worthiness of the vendor is often not the same as the government agency.

Companies should do their best to negotiate short payment terms. In the current environment, 7-15 days is not out of the question, so clients should not be afraid to ask for that. And with so much uncertainty in the market, contracts should be non-cancellable so that manufacturers are not stuck with inventory that they can’t use.

Are you being approached by new entrepreneurs in this space who want to make PPE?

Goldrich: We have been approached by new entrepreneurs but, candidly, we are focused on financing companies with direct experience and who can get the product as quickly as possible without start-up risk. There is enough risk right now out there.

King: Most new companies simply want to buy from approved factories in China and sell to customers in the U.S. There are some U.S. companies that are raising money to move mask manufacturing to the US or changing from manufacturing alcohol or other items to making hand sanitizer etc.

Schuldiner: Every minute of every day we are getting calls from existing clients, entrepreneurs, and referral partners. We are finding that companies may understand how to import and manufacture products, but the further they are away from the supply chain, the more challenging the transaction. If a company has an existing relationship in the chain – if they are already inside the sales chain – the transaction is much more likely succeed. The companies that have never sold to hospital groups or have never had contracts with state and local governments will likely have the most difficulty, unless they have a lending partner with that type of experience and expertise.

Winicour: Yes, absolutely. We’ve seen an uptick in new business in the sector. It’s great to see all the entrepreneurial spirit kicking in right now. And, we’re in a solid position to support those entrepreneurs – private-equity backed and otherwise.

Please discuss some of recent loans to support PPE. Any new deals you could share?

King: We have an existing client that pivoted and has utilized his knowledge of importing from China and his US contacts to fulfill approximately 10 million N-95 and KN95 masks thus far to hospitals as well as state and federal government entities. We just yesterday started to finance a new client in conjunction with one of our friends in the factoring business that is in the hand sanitizer business already, Their orders from their major customers have grown more than 10-fold during the crisis. We are initially supporting more than $25 million of import deliveries over the next 6 weeks and it appears that he will get even more business for hand sanitizer, hand soaps and clean wipes since now he has the financing to match the demand from their customers.

Winicour: We’re actively chasing a few deals right now that we hope to sign up very soon, one of which was in the automotive lubricant business and quickly pivoted their facility to make hand sanitizer. That is another entrepreneur at heart who saw an opportunity not only to give back, but also to take their business to the next level.

Have you had to turn down some of the entrepreneurs entering the PPE manufacturing space?

Winicour: Unfortunately, the answer is yes. As a borrower, no matter what industry you are in, you still have to prove to a lender that your business and financial models are sound. Just because you sell PPE does not mean you automatically qualify for a loan.

I’d also like to add, and I think I speak for everybody in the non-bank asset-based lending world, when I say that most of us, especially the ones with stronger balance sheets and performing portfolios, are open for business and actively looking for new business, both PPE and non-PPE related. We are continuing to fund the small businesses that are the backbone of our economy. You can’t get the word out enough to the small businesses that need liquidity that non-bank ABL is a pocket of finance that is still active out there today, which is important.

.jpg?sfvrsn=f1093d2a_0)